Description

Construction

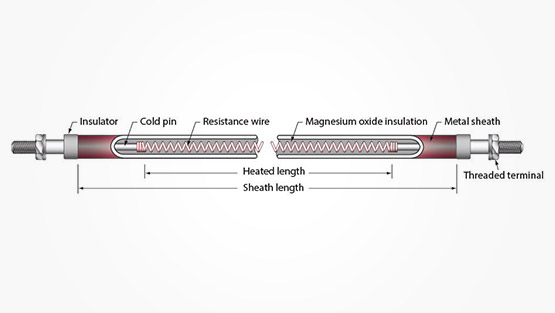

tubular heaters use 80% Nickel 20% Chromium high grade coiled resistance wire as a heating core. This core is welded at both ends to pins that provide a cold section that varies in length depending on the application requirements. The coil-pin assembly is precisely centred inside a heavy gauge, oversize metal tube, and embedded inside a 96% pure, high-grade MgO insulating medium. This assembly is then compacted through a roll-reducing process that reduces the outside tube diameter to its final size, and transforms the MgO matrix into a rock-hard solid that acts as an excellent heat transferring medium, as well as an electric insulation with high dielectric strength. Finally, heaters are annealed inside a high-temperature furnace to eliminate internal stresses accumulated during the cold-forming and roll-reducing process to make them soft. Heating elements are then formed into special shapes, or supplied in their straight form. Proper electrical terminations are added to the final product.

Advantages

- Constructed with epoxy or silicone seals to resist moisture contamination (Oxidation and corrosion resistance)

- Compacted with insulating MgO that allows heat to transfer away from resistance wire to the sheath material and media with faster efficient heat up

- Virtually a limitless array of custom bend formation options, to include adapting heater element around space parameters – to maintain maximized efficient heating

Features

- Incoloy® Sheath material

- Threaded fittings are brazed, crimped or welded to the cold section of the heater

- Nickel chromium Resistance wire is welded to the terminal pins for a stronger positive electric connection to increase the life span of the heater

- MgO insulation fills the sheath to maximize the dielectric strength, promote efficient heat transfer, and prolong the life of the heater

- Stainless steel studs are welded to the terminal pins, which can be covered with protective Ceramic Terminal Covers

- Epoxy or silicone resin seals provide protection from moisture contamination. Seals can rate up to 390°F

Reviews

There are no reviews yet.