Description

Construction

The resistance wire ribbon used in the mica band heater is not restricted to the capabilities of Nichrome wire. Different alloys are considered for different applications. The internal winding is carefully designed to ensure uniform heat distribution throughout the band heater. To maximize the surface-to-surface contact, our mica band heaters are carefully rounded and formed to optimize the grip on a machine barrel. The external metallic protective sheath of Mica band heaters is made of a special alloy, which expands less than the barrel when heated. This difference in thermal expansion makes the heater grip the barrel firmly once it is energized. This improves heat transfer which extends the life of the mica band heater.

Two Piece Construction

Two Piece Construction

Heater Constructions

One Piece Construction: To be used when a heater can be slipped over a barrel without having to expand the heater extensively.

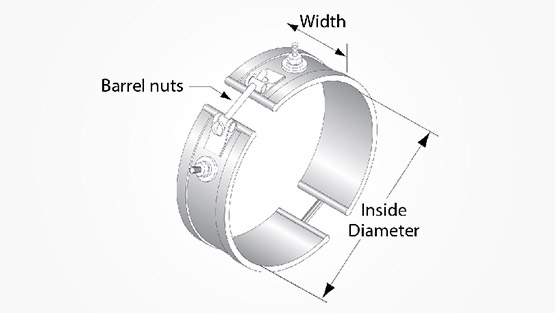

Two Pieces / Multiple Segment Construction: Two piece or multiple segment bands make installation far more convenient and are recommended for applications over a 14″ diameter. Spring loaded clamping is recommended.

Features

- Clamping straps will assure efficient heat transfer

- The low mass design allows quick heat-up and a quick response

- Our design variations provide convenience and heater protection

- Specific watt density : 3.5 W/cm2

- Working temperature upto 250°C

- Element: Nichrome strip/wire

- Diameter range 25mm to 1000mm

- Length range 25mm to 500mm

- High quality Mica having excellent Dielectric strength

Application

- Injection Molding Machine

- Blow Molding Machine

- Extrusion Line

Reviews

There are no reviews yet.